Having first seen this router on the United States Dewalt website last October, I was finally able to track one down here in Canada June 5, 2011.

(7 months later)

Compact routers are great for working with trim, laminates, veneers and many other types of precision woodworking tasks. They're easy to use and maneuver, and offer power enough to tackle a wide variety of projects. The DeWalt DWP611 Variable Speed Compact Router is a true stand out in the compact router category. It features a powerful 1.25 HP motor that will breeze through even the most demanding tasks, and the variable speeds allow you to dial in just the right amount of power the job calls for. The soft start features will reduce the chances of chipping and cracking during startup, and the electronic feedback control helps maintain consistent motor speed throughout the cut. The key to router accuracy is a good view of the cut area, and the DWP611 offers 2 bright LED's and a clear sub base that combine to give you the clear view you need for the most accuracy possible. The DeWalt DWP611 Variable Speed Compact Router is a feature rich and affordable way to take your woodworking projects to the next level.

A very well put together video by

Gord Graff convinced me that this would be my go to router system for small jobs not requiring a router table. I was also interested in something lighter in weight that I could use with my Leigh dovetail jig.

Yesterday I unpacked the router and briefly reviewed the accompanying instructions.

I understand that there are accessories for this router system but they are poorly described in the brochure and apparently not described at all on the website.

I did ask when I purchased the kit if the dealer had been given additional information but apparently they had not.

The accessories I am refering to are pretty much standard fare for routing in today's world. I was expecting information about fence system and further information regarding dust collection which at present,the world considers "optional". I was not expecting these options free but could have used the part numbers for them to obtian info and availabilty.

I did find out from the brochure that in order to equip both the fixed base and the plunge base I will require two fences and two dust collection cups. As there are no part numbers for these accessories the task will be daunting given my experiences over the last seven months with the DeWalt website and their Canadian representatives here in the West.

I managed to find a fence from another router that fits the plunge base but nothing for the fixed base as yet.

Breaking up the kit

The 1-1/4 HP router motor assembly comes with two built-in LED lights. I've found that because of their position and the angle of the lights themselves that they only will illuminate the working area so long as the distance from the motor to the product is greater than 1 inch

Any closer than that and there is no illumination at all around cutting bit. That was one of the features that I was looking forward to with this product and it's surprising that this was not addressed. This will be a problem for those of us that use a jig between the router and the work piece as illustrated here:

I realize that from an engineering perspective they probably had to be machined where they currently sit but it would have been nice had they injection molded a light deflecting prism to reflect the light more directly on the work area. Also I noticed right away that it would've been helpful for set up if the lights could be turned on and off without starting the router motor. They are currently connected to the on-off switch. This makes setting up for a cut harder than it should be.

Both bases are simple to remove from the motor and easy to adjust.

I like the variable speed and the soft start on the motor as it gives me lots of control over cut rates and over heating of bits in some circumstances.

Incidently, at time of writing this blog the best information for spare parts and accessories seems to be

Toolsplus.com Kudos for taking the time to help out the consumer.

What I have now is an extra fence for the fixed and plunge router and a centering device to fix the base for use with a guide bushing.

The auxilary fence is relativley striaght forward to assemble.

You have to remove the 4 screws on plastic base to install the fence to the casting and reverse the process to remove it.

No you don't!

After assembling the jig and taking a closer look at the sub base I find that there are indeed two holes in the base through which I can screw on the auxillary fence. I would be embarrassed with the oversight had I not read the non exisitent instructions.

The unit ( mine) was shipped with the fence positioned upside down. -A bummer for the newbies.

I have no idea what the metric and imperial rulers are supposed to measure. There seems no zero point???

The fence provided for the plunge router base is adapted to fit the Dewalt track saw track and, as such, becomes an expensive substitute for a simple fence.( around $49.00) I managed to find an orphan fence in my tools that will suffice for this router rather than spend another $50 for yet another accessory.

The base centering spindle affair is pretty straight forward but I can't see how it is an "extra" accessory given the fact that you need something to center the base should you ever need to remove it.

Lastly the dust collection cup is now being ordered as it was not listed with the other accessories and the fellow that helped me had to google it to find a part number before he could search the Dewalt tools database to order it.

Somebody at Dewalt needs to review the parts lists and the website to get the information out to the endusers. The dealers say they have no info and don't stock parts and the parts and service say they normally dont stock parts for new products. I find this a bit confusing.

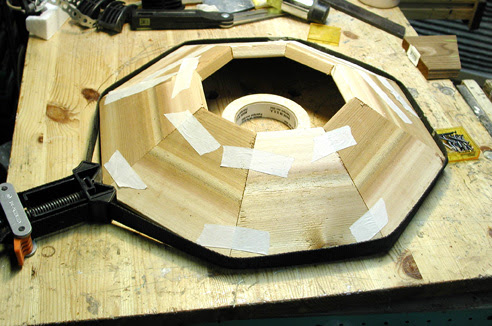

While waiting for the dust collection cup to arrive from Dewalt I ran a box to contain the router , bases and extras to hopefully avoid misplacing parts of the system. The kit came with a small canvas bag but I gave it to my wife to hold her battery cables in her car.

I photostated the cover from the cardborad shipping box and glued them to the boxe. Using finger joints I was able to build the box with 1/4" fir plylwood and finger joints with a sliding lid.

I made up a box for my Fein Muti tool as well.

|

| From |