http://www.members.shaw.ca/boboswin/public/WixeyBevelgaugeobservations/

WixeyBevelgaugeobservations

Thursday, August 11, 2011

Sunday, June 5, 2011

DeWalt DWP611PK 1-1/4 hp Router Kit

|

| From dw611 router kit |

Having first seen this router on the United States Dewalt website last October, I was finally able to track one down here in Canada June 5, 2011.

(7 months later)

Compact routers are great for working with trim, laminates, veneers and many other types of precision woodworking tasks. They're easy to use and maneuver, and offer power enough to tackle a wide variety of projects. The DeWalt DWP611 Variable Speed Compact Router is a true stand out in the compact router category. It features a powerful 1.25 HP motor that will breeze through even the most demanding tasks, and the variable speeds allow you to dial in just the right amount of power the job calls for. The soft start features will reduce the chances of chipping and cracking during startup, and the electronic feedback control helps maintain consistent motor speed throughout the cut. The key to router accuracy is a good view of the cut area, and the DWP611 offers 2 bright LED's and a clear sub base that combine to give you the clear view you need for the most accuracy possible. The DeWalt DWP611 Variable Speed Compact Router is a feature rich and affordable way to take your woodworking projects to the next level.

| From dw611 router kit |

Yesterday I unpacked the router and briefly reviewed the accompanying instructions.

I understand that there are accessories for this router system but they are poorly described in the brochure and apparently not described at all on the website.

I did ask when I purchased the kit if the dealer had been given additional information but apparently they had not.

The accessories I am refering to are pretty much standard fare for routing in today's world. I was expecting information about fence system and further information regarding dust collection which at present,the world considers "optional". I was not expecting these options free but could have used the part numbers for them to obtian info and availabilty.

I did find out from the brochure that in order to equip both the fixed base and the plunge base I will require two fences and two dust collection cups. As there are no part numbers for these accessories the task will be daunting given my experiences over the last seven months with the DeWalt website and their Canadian representatives here in the West.I managed to find a fence from another router that fits the plunge base but nothing for the fixed base as yet.

| From dw611 router kit |

The 1-1/4 HP router motor assembly comes with two built-in LED lights. I've found that because of their position and the angle of the lights themselves that they only will illuminate the working area so long as the distance from the motor to the product is greater than 1 inch

| ||

| From dw611 router kit |

| ||

| From dw611 router kit |

| From dw611 router kit |

Both bases are simple to remove from the motor and easy to adjust.

I like the variable speed and the soft start on the motor as it gives me lots of control over cut rates and over heating of bits in some circumstances.

Incidently, at time of writing this blog the best information for spare parts and accessories seems to be Toolsplus.com Kudos for taking the time to help out the consumer.

What I have now is an extra fence for the fixed and plunge router and a centering device to fix the base for use with a guide bushing.

|

| From dw611 router kit |

The auxilary fence is relativley striaght forward to assemble.

|

| From dw611 router kit |

You have to remove the 4 screws on plastic base to install the fence to the casting and reverse the process to remove it.

No you don't!

After assembling the jig and taking a closer look at the sub base I find that there are indeed two holes in the base through which I can screw on the auxillary fence. I would be embarrassed with the oversight had I not read the non exisitent instructions.

The unit ( mine) was shipped with the fence positioned upside down. -A bummer for the newbies.

I have no idea what the metric and imperial rulers are supposed to measure. There seems no zero point???

The fence provided for the plunge router base is adapted to fit the Dewalt track saw track and, as such, becomes an expensive substitute for a simple fence.( around $49.00) I managed to find an orphan fence in my tools that will suffice for this router rather than spend another $50 for yet another accessory.

|

| From dw611 router kit |

The base centering spindle affair is pretty straight forward but I can't see how it is an "extra" accessory given the fact that you need something to center the base should you ever need to remove it.

|

| From dw611 router kit |

Lastly the dust collection cup is now being ordered as it was not listed with the other accessories and the fellow that helped me had to google it to find a part number before he could search the Dewalt tools database to order it.

Somebody at Dewalt needs to review the parts lists and the website to get the information out to the endusers. The dealers say they have no info and don't stock parts and the parts and service say they normally dont stock parts for new products. I find this a bit confusing.

While waiting for the dust collection cup to arrive from Dewalt I ran a box to contain the router , bases and extras to hopefully avoid misplacing parts of the system. The kit came with a small canvas bag but I gave it to my wife to hold her battery cables in her car.

|

| From dw611 router kit |

|

| From dw611 router kit |

|

| From |

Tuesday, May 17, 2011

Narex mortise Chisels Set of 5

I bought a five piece set of Narex mortise chisels and so far have had an opportunity to actual work with one.

I'm quite pleased with the fit and finish and this steel quality which seems to be just right for my liking. Not too brittle, takes an edge quickly and seems to sharpen without leaving too much curl on the cutting-edge.(Rc59) They have a nice weight to them in a nice feel in my hand and the blades are definitely long enough to be able to hold the blade in alignment while gently tapping the butt to form the mortise.

I'm a bit short of time this weekend for various reasons so I gave the half-inch chisel a bit of a flattening on the back and re-honed the long bevel edge on the front so I could try the chisel on some wood today.

I grabbed a piece of 2 x 4 Spruce stock , flattened the top with a Jack plane, and dropped the mortise with her one half-inch bit in my Triton router.

As shown in the following picture the half-inch mortise is an excellent fit to the half-inch router bit I am using and it actually took just a few seconds to square a each end of the of the mortise.

This is a picture of the finished mortise and although it is not a textbook example using a hardwood it has given me confidence to go ahead and finish honing the other four chisels.

The set consists of a 3/16, 1/4, 5/16, 3/8, and 1/2" chisels.

They come as shown with blade guards but do not include a fancy case which I generally end up tossing out anyway.

They're modestly priced and a pleasure to work with. I found mine at the Valley tools and I do understand that this brand from Czechoslovakia is also available at Highland woodworking in the US.

I'm quite pleased with the fit and finish and this steel quality which seems to be just right for my liking. Not too brittle, takes an edge quickly and seems to sharpen without leaving too much curl on the cutting-edge.(Rc59) They have a nice weight to them in a nice feel in my hand and the blades are definitely long enough to be able to hold the blade in alignment while gently tapping the butt to form the mortise.

|

| From narex mortise chisels |

I'm a bit short of time this weekend for various reasons so I gave the half-inch chisel a bit of a flattening on the back and re-honed the long bevel edge on the front so I could try the chisel on some wood today.

|

| From narex mortise chisels |

|

| From narex mortise chisels |

I grabbed a piece of 2 x 4 Spruce stock , flattened the top with a Jack plane, and dropped the mortise with her one half-inch bit in my Triton router.

|

| From narex mortise chisels |

As shown in the following picture the half-inch mortise is an excellent fit to the half-inch router bit I am using and it actually took just a few seconds to square a each end of the of the mortise.

|

| From narex mortise chisels |

|

| From narex mortise chisels |

The set consists of a 3/16, 1/4, 5/16, 3/8, and 1/2" chisels.

They come as shown with blade guards but do not include a fancy case which I generally end up tossing out anyway.

They're modestly priced and a pleasure to work with. I found mine at the Valley tools and I do understand that this brand from Czechoslovakia is also available at Highland woodworking in the US.

Wednesday, February 2, 2011

Modifying trim routers for template gauges.

I find that my big 2 and 3 hp routers are not up to the delicate task of routing patterns or inlays .

I was not prepared to ad yet another dedicated tool to my arsenal to I decided to modify a couple of my weapons to accept brass bushing's biggest problem for me was getting the bushing set dead center over the chuck and the template base drilled to exactly holed that position when screwed back on the base. Trial and error lead me to use the centering pin shown here to mark center then drill the template hole first.

Now, inserting the template guide baking to the lexan I could mark and drill for the set screws. In thus situation I am making the jig to retrofit my Rotozip general purpose trimmer.. It just sits in the shop most of the time as it was limited to 2-3 tasks and now can handle a 4th.I used two sheets of lexan here, One has a cut out to receive the Rotozip base and the other forms the base with the hole for the bushing. I joined them together with epoxy. the base has yet to be trimmed down as the epoxy was slow setting yesterday with the humidity.Heres the completed jig for the router zip:That's piece of scrap aluminum with set screws to hold the front of the jig where the metal strip at the back holds the guide when attached to the black screw on the height adjustment. This one is fitted to a cheap under $40.00 router that is ultra light with variable speed. I can get a larger bit in here to hog out the inside of a pattern quickly then switch to the inlay bit to refine the edges for the actual inlay.I suppose I could have been a bit neater but it works.So why did I do this?Here's what I am trying to get perfected; Iwant to be able to cut a pattern quickly and efficiently without a lot of bit changes and or the possibility of running out of the pattern.I felt I needed more tactical control than I was getting with full sized routers.I'm not quite spot on but the results are encouraging.

Tuesday, January 18, 2011

Making an Octagonal Bird feeder.

I haven't blogged before so bear with me while I find out where the rocks are.

It looks like I managed to get pictures in here so here goes the story:

BTW, that is a Downey woodpecker doing a close up investigation.

I have been fussing with critters all my life and birds are among my favourites.

By attracting them I gain the benefit of their company and the side benefit of their constant insect control.

These feeders are 8 sided and fun to build in the shop.

I have found some work arounds for the windows and the feed area that could save you some time.

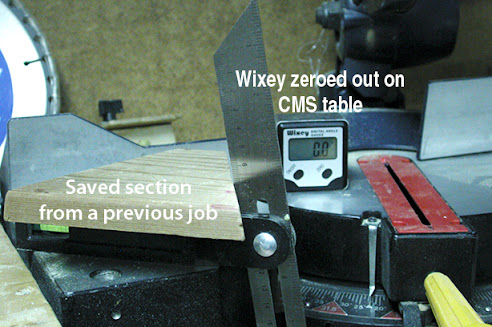

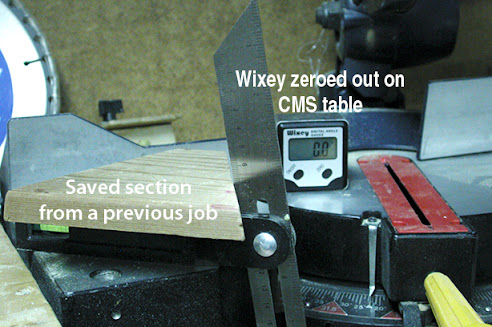

I like to keep a piece of cut stock from a previous feeder to use as a guide to set up my saw

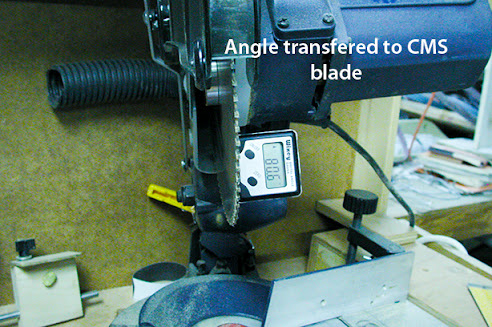

For future cuts but I am finding that this wixey angle gauge is taking a lot of the set up time out of the job.

Now I just set the angle off the number of segments and let the Wixey figure out the compound angle for the saw.

Here's how it works:

1.Take the angle off an old segment as I do here or calculate it from a table.

there are numerous on the net and some in Excel if you prefer.

2. Set the Wixey on the saw table and zero it out.

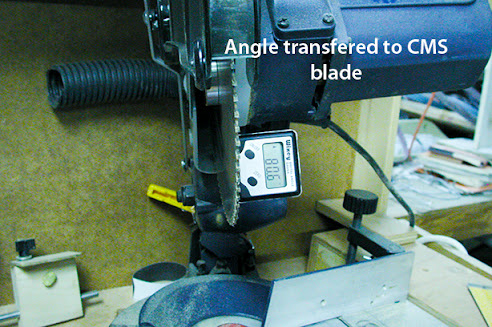

3. Using a steel miter gauge set the Wixey on it a measure the angle difference vs the table and the gauge.

Transfer the Wixey to your saw blade and set in the same angle you got from the bevel gauge.

The diameter of your roof will vary with the stock you choose but the angle of slope will remain the same.

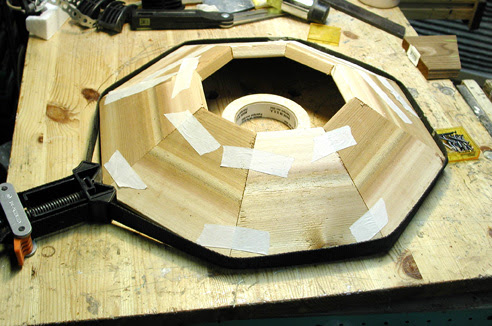

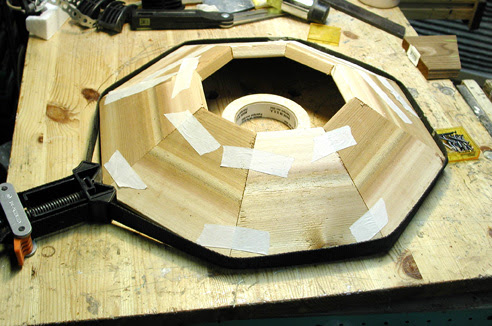

4. Saw up 4 pieces and set them with masking tape against a flat board and check your fit.

Adjust if necessary.

If they are a fit, cut the other 4 pieces and get ready to glue them.

You pretty much should use polyurethane glue ( Elmers or Gorilla for example) to get a weather proof seal as Most of the joints are end grain and will be sitting in moisture alot.

Wear gloves with this Stuff, it stains your hands.

Use it sparingly and spray the glued surface with water to hasten the cure.

I apply the glue on one surface and wet the mating surface.

to be continued...

It looks like I managed to get pictures in here so here goes the story:

BTW, that is a Downey woodpecker doing a close up investigation.

I have been fussing with critters all my life and birds are among my favourites.

By attracting them I gain the benefit of their company and the side benefit of their constant insect control.

These feeders are 8 sided and fun to build in the shop.

I have found some work arounds for the windows and the feed area that could save you some time.

I like to keep a piece of cut stock from a previous feeder to use as a guide to set up my saw

For future cuts but I am finding that this wixey angle gauge is taking a lot of the set up time out of the job.

Now I just set the angle off the number of segments and let the Wixey figure out the compound angle for the saw.

Here's how it works:

1.Take the angle off an old segment as I do here or calculate it from a table.

there are numerous on the net and some in Excel if you prefer.

2. Set the Wixey on the saw table and zero it out.

3. Using a steel miter gauge set the Wixey on it a measure the angle difference vs the table and the gauge.

Transfer the Wixey to your saw blade and set in the same angle you got from the bevel gauge.

The diameter of your roof will vary with the stock you choose but the angle of slope will remain the same.

4. Saw up 4 pieces and set them with masking tape against a flat board and check your fit.

Adjust if necessary.

If they are a fit, cut the other 4 pieces and get ready to glue them.

You pretty much should use polyurethane glue ( Elmers or Gorilla for example) to get a weather proof seal as Most of the joints are end grain and will be sitting in moisture alot.

Wear gloves with this Stuff, it stains your hands.

Use it sparingly and spray the glued surface with water to hasten the cure.

I apply the glue on one surface and wet the mating surface.

to be continued...

Sunday, January 16, 2011

Thin strip table saw gauge

I needed a jig to allow me to cut consistent thin strips away from the fence and the potential for binding and possbly nicking the fence. I have the Grr ripper but sometimes need a strip too narrow for this jig.(1/4" minimum)

I saw this in ShopNotes or similar and never got around to making it.

It's really simple and only needs a routed slot and a bolt to carry a small bearing on the nose. I picked up the miter slot fittings from Workshop Supply here in Canada.

You can fine tune this with measuring bars and cut strip after strip just by moving the fence in to the bearing surface.

If you use the Grr-ripper you can set it way back and set the Gripper up ahead of it to carry the cut through the blade.

Bob

|

| From THIN STRIP TS JIG |

I saw this in ShopNotes or similar and never got around to making it.

It's really simple and only needs a routed slot and a bolt to carry a small bearing on the nose. I picked up the miter slot fittings from Workshop Supply here in Canada.

|

| From THINS STRIP TS JIG |

|

| From THINS STRIP TS JIG |

|

| From THINS STRIP TS JIG |

Bob

Thursday, January 13, 2011

Working punky wood in a maple burl

These pics tell the whole story.

The fellow that trims my trees around home dropped off this huge burl about 2 years ago.

This is about 1/4 of it so far.

I just keep running out of time .

Time is not my friend.

Bob

The fellow that trims my trees around home dropped off this huge burl about 2 years ago.

This is about 1/4 of it so far.

I just keep running out of time .

Time is not my friend.

Bob

Wednesday, January 12, 2011

MAKE a birdhouse from a log and some fence board

Here's a "project" for a rainy day.

http://members.shaw.ca/boboswin/public/birdhouse%20project/Birchlogbirdhouse/

Bob

Here's a "project":http://members.shaw.ca/boboswin/public/birdhouse%20project/Birchlogbirdhouse for a rainy day

http://members.shaw.ca/boboswin/public/birdhouse%20project/Birchlogbirdhouse/

Bob

Here's a "project":http://members.shaw.ca/boboswin/public/birdhouse%20project/Birchlogbirdhouse for a rainy day

Tuesday, January 4, 2011

"These pics tell the whole story":http://www.members.shaw.ca/boboswin/public/Burlcuttingtechnique/

The fellow that trims my trees around home dropped off this huge burl about 2 years ago.

This is about 1/4 of it so far.

I just keep running out of time .

Time is not my friend right now.

Bob

The fellow that trims my trees around home dropped off this huge burl about 2 years ago.

This is about 1/4 of it so far.

I just keep running out of time .

Time is not my friend right now.

Bob

Bandsaw log sled and resaw fence for any bandsaw

I cant take credit for this design but after chasing around the internet for a while I landed on this simple solution.

I believe Mike in Paradise Newfoundland may be the originator.

It's just a cradle with a parallel "keel" to fit into the bandsaw miter slot.

It uses a 1/2" pipe clamp as the log gripper.

*One caveat:* the logs are heavy and can tilt the BS table. I will be cutting a support stick for under the table shortly to prevent this.

I will also be drilling some additional holes to reposition the bar clamp in the cradle ends as the need arises.

To set the depth of cut I just set my fence to the correct width and slip the first end of the log up to it then pass the entire log past the blade and set the back end.

p.s. I should have used my 3/4" resaw blade but forgot to change it in my haste to make shop time more valuable

Well it didn't take long to find out that I needed an out feed table/slider on these logs. They are quite heavy and difficult to handle by yourself so I rigged up this slider that rests on top of my outfeed table for the table saw.

Here's a different shot of it in case you want to copy me .

The frame is notched to fit the miter slot on my bandsaw table and I attached it using a spring clamp for now.

The actual sled lines up with it and slides into a trough to keep it lined up when it exits the blade.

Here's shot of the rig packed up for storage I wanted the outfeed to nest in the sled to save space and it does .

I still have to modify the bar clamp and stabilize the bandsaw table for the additional weight but the hard stuff is done now.

Here's the modification to the bar clamp with one of two screws in the steel plate dangling down in front of the adjustable end of the bar clamp. I am trying to prevent rotation of the log during movement.

p.s. the screws are ground to a dull point

I also added an led light to the setup today using a flexible book light and a couple of magnets in a block of wood. I have to remember to turn it off though.

Heres a shot of the light in place on the saw.

They are really inexpensive now and this one came with 5 extra batteries.(All for a buck!)

Now we are going to need a* resaw fence* for the slabbed lumber and the exotic stuff from the lumber vendors.

I just used scraps of this and that to build a box over the bandsaw fence to extend the height .

This should prevent cutting "wedgies".

Here's a shot from the back side showing how it sits over the fence.

On Saturday I will get some slotted nuts to secure it when I'm slicing.

I deliberately used MDF for the face of the fence as I have found it more stable than other solutions.

Here you can see a test piece sliced into three.

I ran the piece through the saw a couple of times to give myself a flat bottom to run past the blade and slipped it through with a push stick at the end.

The last shot shows the three pieces flat on the table.

The light I rigged up yesterday is comming in quite handy.

I believe Mike in Paradise Newfoundland may be the originator.

It's just a cradle with a parallel "keel" to fit into the bandsaw miter slot.

It uses a 1/2" pipe clamp as the log gripper.

*One caveat:* the logs are heavy and can tilt the BS table. I will be cutting a support stick for under the table shortly to prevent this.

I will also be drilling some additional holes to reposition the bar clamp in the cradle ends as the need arises.

To set the depth of cut I just set my fence to the correct width and slip the first end of the log up to it then pass the entire log past the blade and set the back end.

p.s. I should have used my 3/4" resaw blade but forgot to change it in my haste to make shop time more valuable

Well it didn't take long to find out that I needed an out feed table/slider on these logs. They are quite heavy and difficult to handle by yourself so I rigged up this slider that rests on top of my outfeed table for the table saw.

Here's a different shot of it in case you want to copy me .

The frame is notched to fit the miter slot on my bandsaw table and I attached it using a spring clamp for now.

The actual sled lines up with it and slides into a trough to keep it lined up when it exits the blade.

Here's shot of the rig packed up for storage I wanted the outfeed to nest in the sled to save space and it does .

I still have to modify the bar clamp and stabilize the bandsaw table for the additional weight but the hard stuff is done now.

Here's the modification to the bar clamp with one of two screws in the steel plate dangling down in front of the adjustable end of the bar clamp. I am trying to prevent rotation of the log during movement.

p.s. the screws are ground to a dull point

I also added an led light to the setup today using a flexible book light and a couple of magnets in a block of wood. I have to remember to turn it off though.

Heres a shot of the light in place on the saw.

They are really inexpensive now and this one came with 5 extra batteries.(All for a buck!)

Now we are going to need a* resaw fence* for the slabbed lumber and the exotic stuff from the lumber vendors.

I just used scraps of this and that to build a box over the bandsaw fence to extend the height .

This should prevent cutting "wedgies".

Here's a shot from the back side showing how it sits over the fence.

On Saturday I will get some slotted nuts to secure it when I'm slicing.

I deliberately used MDF for the face of the fence as I have found it more stable than other solutions.

Here you can see a test piece sliced into three.

I ran the piece through the saw a couple of times to give myself a flat bottom to run past the blade and slipped it through with a push stick at the end.

The last shot shows the three pieces flat on the table.

The light I rigged up yesterday is comming in quite handy.

a simple plane for a site level.

This is such a simple project I hate to bother you with it but I thought it might be the kind of project that may stay in your family.

I spent about 10-12 dollars on parts and the rest took about a 1/2 hour in the shop.

If you have a WW buddy it could get you some brownie points around x-mas or Ramadan or YK or whatever.

Cheers Bob

I spent about 10-12 dollars on parts and the rest took about a 1/2 hour in the shop.

If you have a WW buddy it could get you some brownie points around x-mas or Ramadan or YK or whatever.

Cheers Bob

What? another birdhouse?

|

| From teaching kids |

Click on the red text above to follow us on this one.

Birdhouse from a log with the help of a wood lathe

Here's a simple way to build a birdhouse from a bit of firewood and some fence board scraps.

Just click on the red writing for a pictorial.

Just click on the red writing for a pictorial.

An oval hand mirror

I have been wanting to try one of these for a while now and got the first pattern off the paper in into wood today.

First thing to do is determine how much border you want to encircle the mirror and then cut and accurate pattern of the actual glass to serve as a template for your router inlay kit.

I sticky back taped the mirror to bandsaw a piece of 1/4"MDF and trimmed it to the shape with a bearing guided router bit.

Next step was to refine the mirror back template so the oval would line up with the axis of the handle.

Once the recess for the mirror was routed the body could be cut out on the bandsaw and refined

The thickness sander brought us to the right thickness and refined the surfaces.

A light skip around the router table witha round over bit and we are starting to see daylight.

The mirror seems a good fit and the bezel looks relatively even round it.

here's the back with the mirror out on the side.

I am contemplating an inlay for the back to kind of dress it up a bit.

... to be continued.

First thing to do is determine how much border you want to encircle the mirror and then cut and accurate pattern of the actual glass to serve as a template for your router inlay kit.

|

| From mirror oval |

I sticky back taped the mirror to bandsaw a piece of 1/4"MDF and trimmed it to the shape with a bearing guided router bit.

|

| From mirror oval |

Next step was to refine the mirror back template so the oval would line up with the axis of the handle.

Once the recess for the mirror was routed the body could be cut out on the bandsaw and refined

|

| From mirror oval |

|

| From mirror oval |

|

| From mirror oval |

|

| From mirror oval |

I am contemplating an inlay for the back to kind of dress it up a bit.

|

| From mirror oval |

Subscribe to:

Comments (Atom)